Thanks to their wide range of types, mobac driven winders and payoffs are ideal for winding and rewinding almost all types of wire, cable, strand, rope, tape, wire rope, etc. Wherever unwinding or winding is required, mobac offers appropriate machines.

Winding machines

Winder and Payoffs

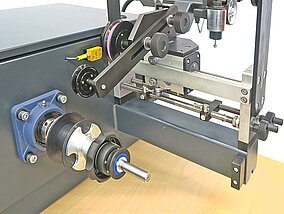

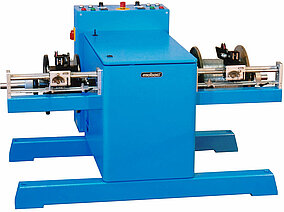

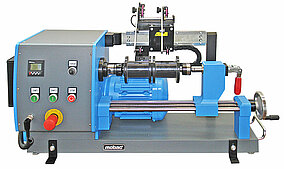

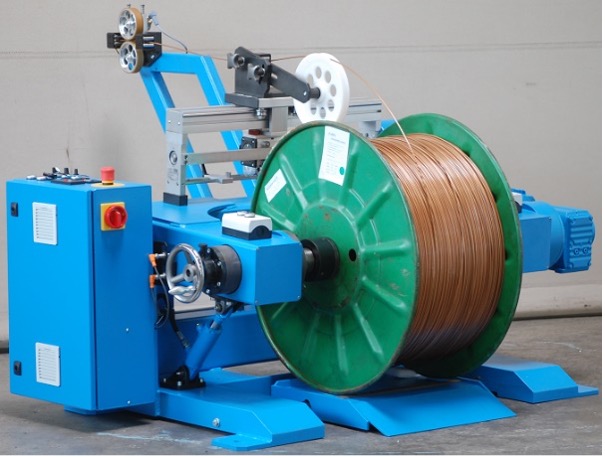

Winder for bobbins

The mobac rewinders are specially designed for the precise and efficient winding of wires, cables and ropes onto spools. The product range includes models with single-sided or double-sided spool mounting.

Description

- Spool diameter: 20-1250 mm

- Wire diameter: 0.05-25.0 mm

- Maximum winding width: up to 800 mm

- Speed range: 0-6000 rpm (depending on model)

- Drive: Three-phase motor with frequency converter – up to max. 11 kW

- Mechanical installation: Uhing type Kinemax or RG15 – RG 40

- Electronic installation – with servo motor and control unit

- Optical installation – with laser scanning and control

- Equipment: Revolution counter or meter counter with preselection and automatic stop

- Coil holder: shaft mounted on one side with Easylock clamping system or similar incl. Driver

- Maximum spool weight: up to 1200 kg

- Spool change time: <15 seconds

- Transparent and painted protective hoods with monitoring

- Working signal lights or signal horns (depending on model)

- Approach and stop ramps programmable via frequency inverter

- Independent control with double-sided spool pick-up

- Dancer accumulator for adjusting the winding speed and tensile force (depending on model) (optional)

- Constant digital speed display (optional)

- Modular design for different applications

- Use for various wire materials such as copper, aluminum, steel, plastic, carbon fiber, ropes

- Customized adaptations possible

Optional

- Meter counter / revolution counter

- Wire break switch

- Large digital display

- Foldable operating consoles

- Protective device

- Under-sink frame

- Dancer accumulator

- Capstan

- Wire clamp (mech./electr.)

- Interfaces e.g. for printers, memory testers etc.

Terminal for entering and saving winding data

Controller with interface for PLC communication - Product-specific wire guides

- Fixed and swivel castors under the payoffs

Catalog

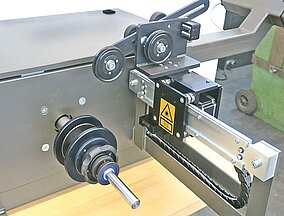

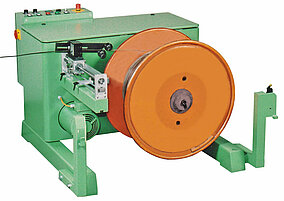

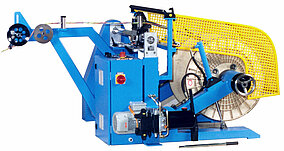

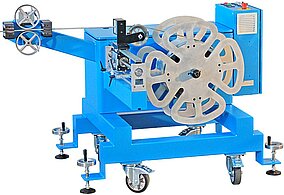

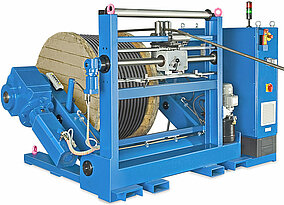

Winder with pinole system

Pinole winders from mobac enable the precise winding of materials onto spools. They are available with both single-sided and double-sided spool holders and offer flexibility for various applications.

Description

- Bobbin diameter: 250-1800 mm

- Wire diameter: 0.5-35 mm

- Maximum winding width: up to 1400 mm

- Speed range: 0-3000 rpm (depending on model)

- Drive: Three-phase motor with frequency converter – up to max. 15 kW

- Mechanical installation: Uhing type Kinemax or RG15 – RG 60

- Electronic installation – with servo motor and control unit

- Optical installation – with laser scanning and control

- Equipment: Revolution counter or meter counter with preselection and automatic stop

- Spool holder: via a sleeve incl. Driver

- Spool lifting via manual or electro-hydraulic system

- Spool tensioning by hand or via electrohydraulics

- Maximum spool weight: up to 5000 kg

- Spool change time: <30 seconds

- Transparent and painted protective hoods with monitoring

- Working signal lights or signal horns (depending on model)

- Approach and stop ramps programmable via frequency inverter

- Dancer accumulator for adjusting the winding speed and tensile force (depending on model) (optional)

- Constant digital speed display (optional)

- Modular design for different applications

- Use for various wire materials such as copper, aluminum, steel, plastic, carbon fiber, ropes

- Customized adaptations possible

Optional

- Meter counter / revolution counter

- Wire break switch

- Large digital display

- Foldable operating consoles

- Protective device

- Dancer accumulator

- Capstan

- Wire clamp (mech./electr.)

- Coil reel for strapless winding

- Interfaces e.g. for printers, memory testers etc.

Terminal for entering and saving winding data

Controller with interface for PLC communication - Product-specific wire guides

Catalog

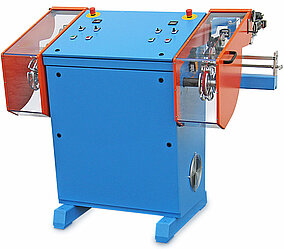

Coil winder

The coil winders from mobac are specially designed for handling coils. They are available in single-sided and double-sided versions and ensure efficient and safe winding of coils of different sizes.

Description

- Coil diameter: 120-1000 mm

- Wire diameter: 0.5-15.0 mm

- Maximum winding width: up to 400 mm

- Speed range: 0-3000 rpm (depending on model)

- Drive: Three-phase motor with frequency converter – up to max. 7 kW

- Mechanical installation: Uhing type Kinemax or RG15 – RG 40

- Electronic installation – with servo motor and control unit

- Optical installation – with laser scanning and control

- Equipment: Revolution counter or meter counter with preselection and automatic stop

- Coil holder: shaft mounted on one side with Easylock clamping system or similar

- Maximum coil weight: up to 800 kg

- Coil change time: <60 seconds

- Transparent and painted protective hoods with monitoring

- Working signal lights or signal horns (depending on model)

- Approach and stop ramps programmable via frequency inverter

- Independent control with double-sided spool pick-up

- Dancer accumulator for adjusting the winding speed and tensile force (depending on model) (optional)

- Constant digital speed display (optional)

- Modular design for different applications

- Use for various wire materials such as copper, aluminum, steel, plastic, carbon fiber, ropes

- Customized adaptations possible

Optional

- Meter counter / revolution counter

- Wire break switch

- Large digital display

- Foldable operating consoles

- Protective device

- Under-sink frame

- Dancer accumulator

- Capstan

- Wire clamp (mech./electr.)

- Interfaces e.g. for printers, memory testers etc.

Terminal for entering and saving winding data

Controller with interface for PLC communication - Product-specific wire guides

- Fixed and swivel castors under the payoffs

Catalog

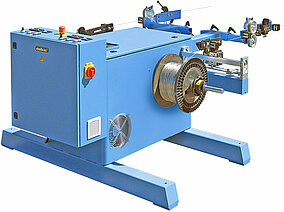

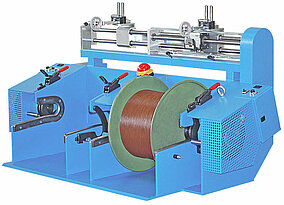

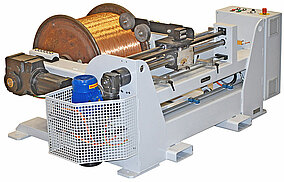

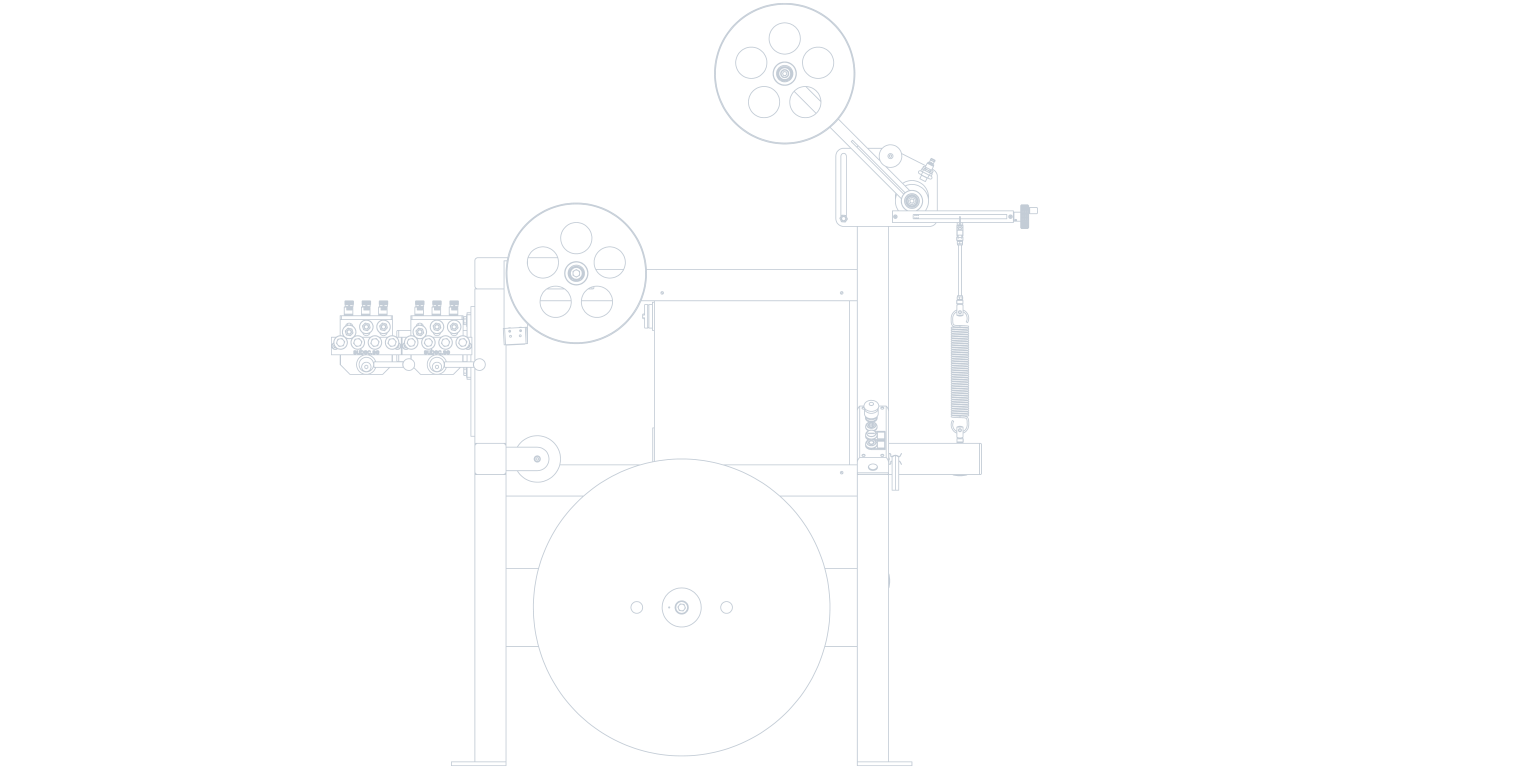

Combined winder and rewinder

mobac offers combined winders and rewinders that enable the simultaneous winding and rewinding of materials. These machines are ideal for processes that require both functions and offer high efficiency and precision.

Description

- Spool diameter: 400-1800 mm

- Winding material diameter: 0.5-35 mm

- Maximum spool width: 1000 mm

- Winding spindle speed: 0-300 rpm

- Maximum spool weight: approx. 5000 kg

- Wire laying: Uhing type RG 30 – RG 60

Electronic installation – with servo motor and control unit - Drive: Three-phase motor up to 17.5 kW

- Machine weight: up to approx. 2500 kg

- Spool change time: <60 seconds

- Hydraulic spool lifting: yes

- Tensioning of the spools by means of quill: hydraulic at the touch of a button

- Functionality: both unwinding and rewinding of steel cables, cables etc.

- Remote control: control of speed, tractive force, start and stop

- Programming: Freely programmable start and stop ramps via frequency inverter

Optional

- Meter counter

- Constant digital speed display (m/min)

- Large digital display

- Foldable operating consoles

- Protective device

- Dancer accumulator

- Wire clamp (mech./electr.)

- Interfaces e.g. for printers, memory testers etc.

Terminal for entering and saving winding data

Controller with interface for PLC communication

Catalog

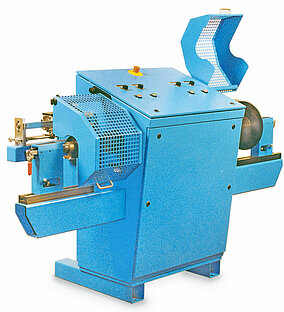

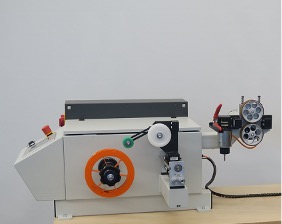

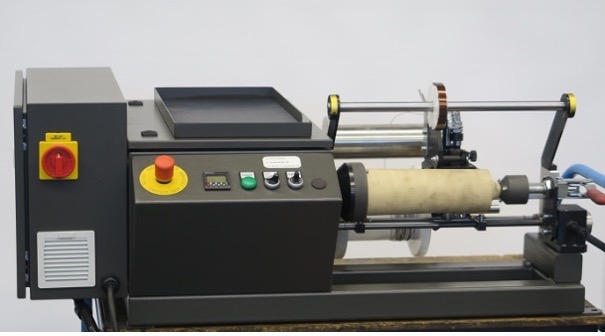

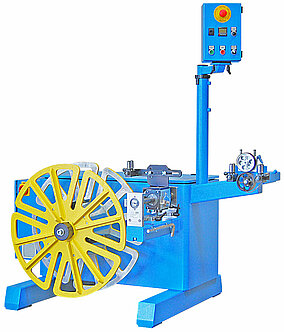

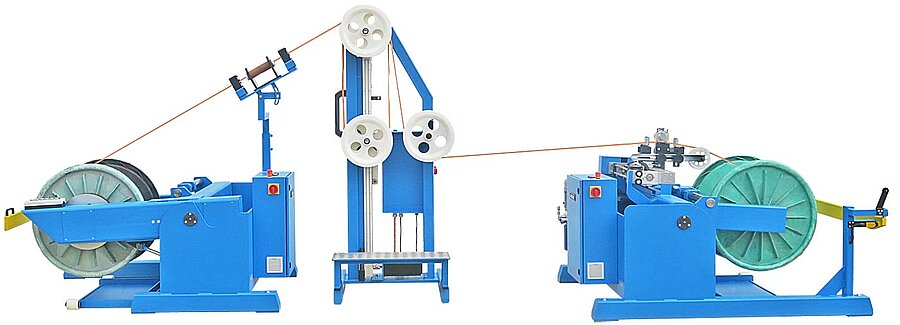

Rewinder

The mobac rewinders are designed for the precise rewinding of materials from one reel to another. They ensure gentle handling of the material and are suitable for different reel sizes and types.

Description

- Rewinding of wires (copper, aluminum, brass, steel) from carrierless coils onto spools or from spool to spool

- Maximum wire diameter on coils: approx. 3 mm

- Rewinder optionally with pre-programmable meter counter with automatic stop

- Coil pay-off: Flyer pay-off with hysteresis break and straightener for tension build-up and wire direction

- Additional equipment with dancer accumulator

- Rewinder with wire laying and synchronous motor, controlled by dancer control

- Driven quill unwinder with tension and speed control via dancer accumulator (optional)

- Spool tension via sleeve or via shaft mounted on one side

- Suitable for spools with a flange diameter of 355-1000 mm

- For cables and ropes with diameters of 0.5-18.0 mm

- Maximum speed: up to 200 m/min (with flyer discharge)

- Maximum speed: up to 600 m/min (from spool to spool)

- Driven dancer accumulator with servomotor for tension control (optional)

- Storage path: 5-50 meters

- Tensile force range: 4-200 N

- Quill rewinder with solid rolling ring gear installation

Optional

- Meter counter / revolution counter

- Wire break switch

- Large digital display

- Foldable operating consoles

- Protective device

- Dancer accumulator

- Wire clamp (mech./electr.)

- Interfaces e.g. for printers, memory testers etc.

Terminal for entering and saving winding data

Controller with interface for PLC communication - Product-specific wire guides

Catalog