Winding machines such as wire pay-offs, pay-off flyers, take-ups and pay-offs from mobac are ideally suited for almost all types of winding and unwinding of wire, cable, strand, rope, tape, wire rope, etc. due to their variety of types. Wherever unwinding or winding is required, mobac offers appropriate machines: as a single flyer or as a complete frame for single or multiple unwinding with up to 24 winding positions (or more). By using and combining different wire tension controls and brakes, interference immunity is achieved even at high speeds or with sensitive material.

Winding machines

Flyer Payoffs

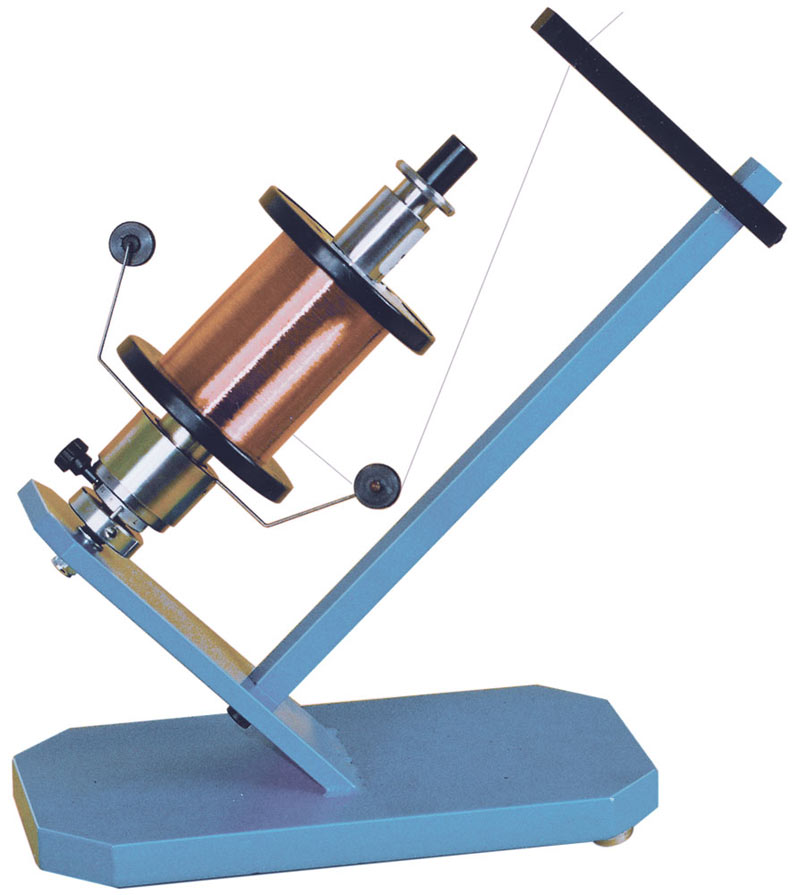

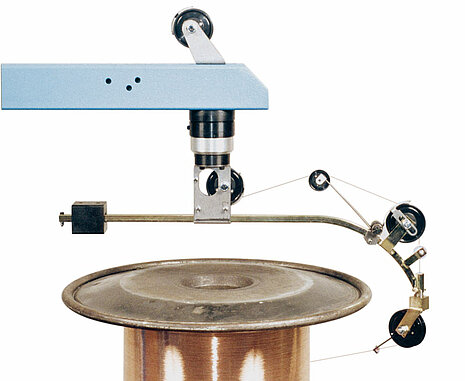

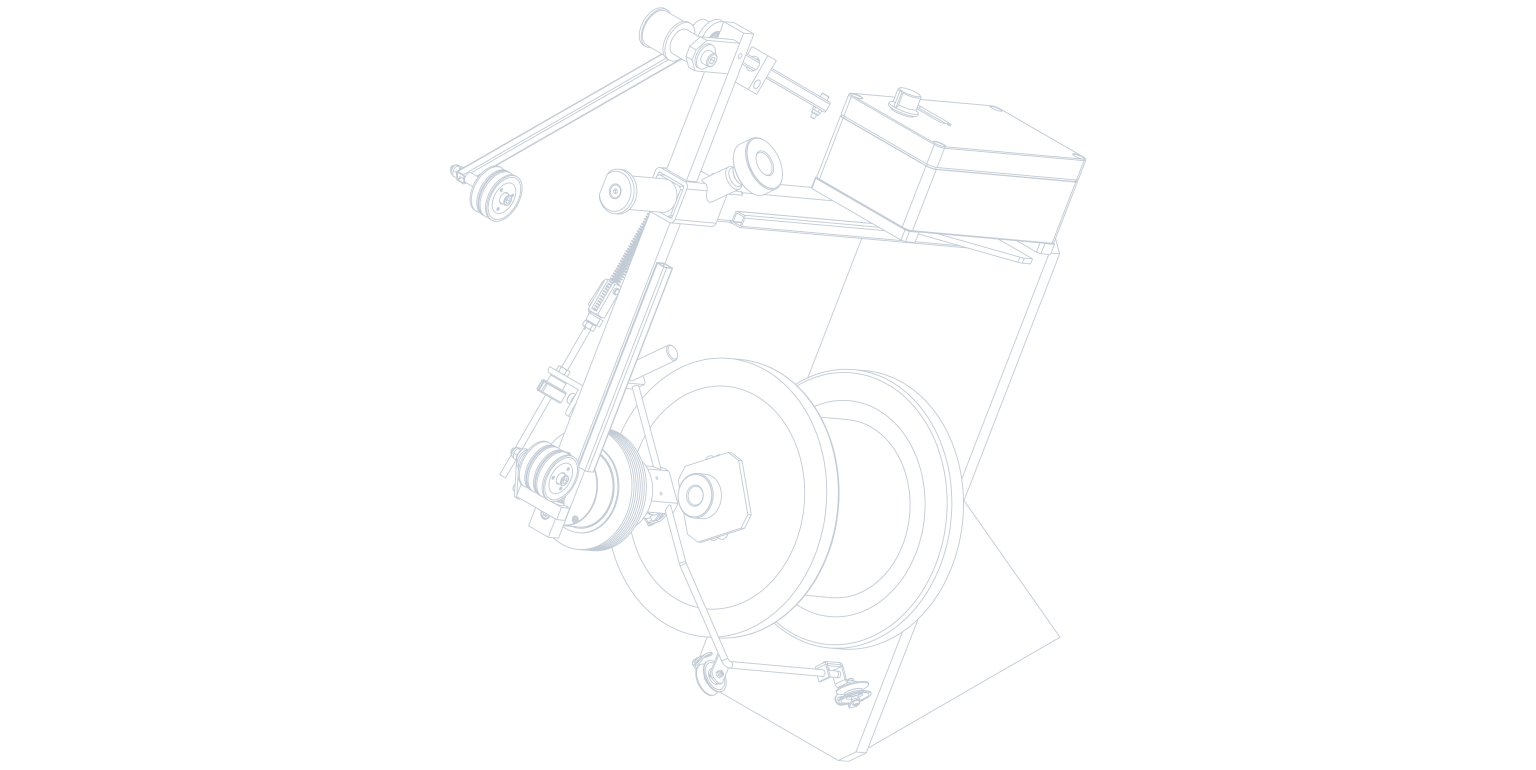

Flyer for frame mounting

Flyers for frame mounting offer a robust and reliable solution for mounting on fixed frames. They are ideal for applications that require high precision and stability.

Description

- Suitable for spool diameters from 80 to 1250 mm

- Maximum wire speed: 800 m/min

- Wire tension range: up to 50 N

- Supported wire diameters:

- Copper and aluminum wire: 0.1 to 3 mm

- Steel wire (hard): up to 1.8 mm

- Steel wire (soft): up to 2.2 mm

- Multi-wire capacity: up to 8 x 0.65 mm

- Equipment: Hysteresis brake, magnetic particle brake with power supply unit

Optional

- Universally adjustable deflection roller

- Flyer arm for both directions of rotation

- Fast flyer arm made from fiberglass

- for mounting on an existing frame

- Compensator

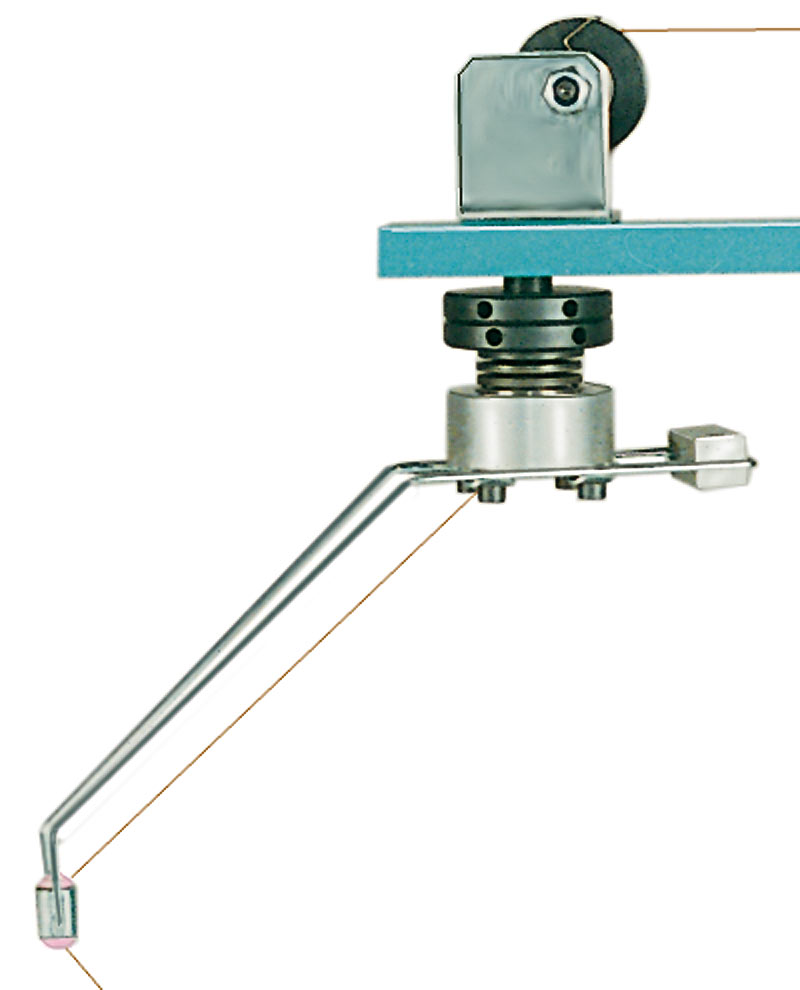

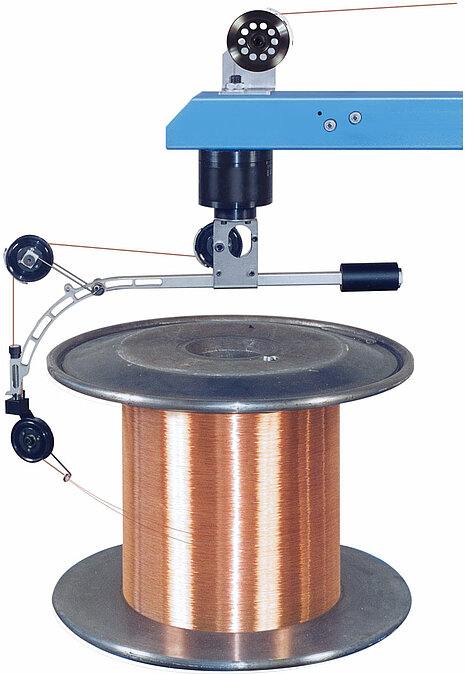

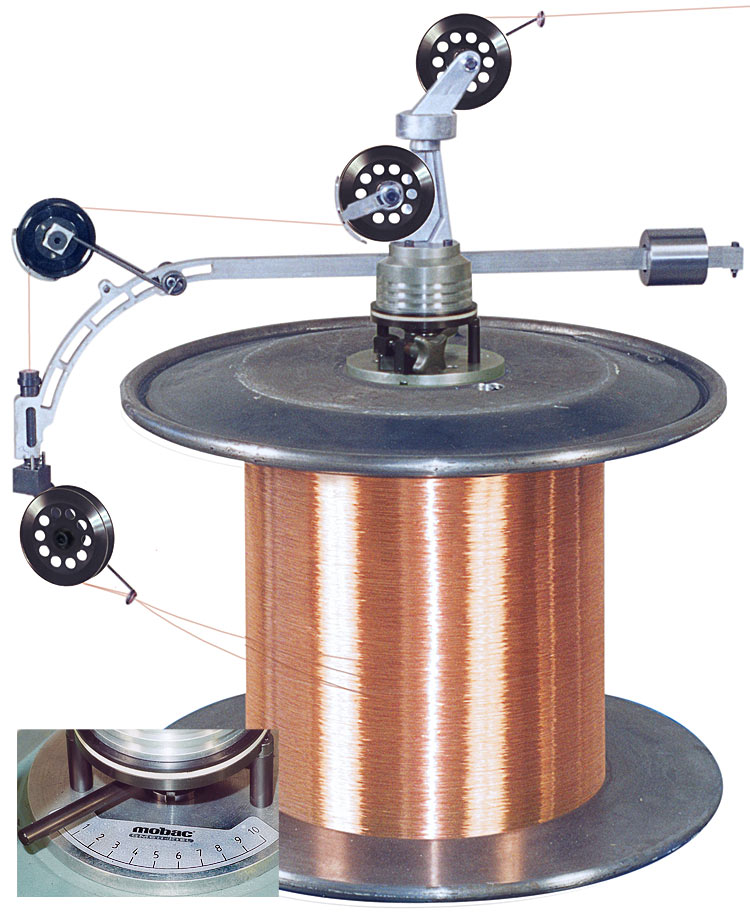

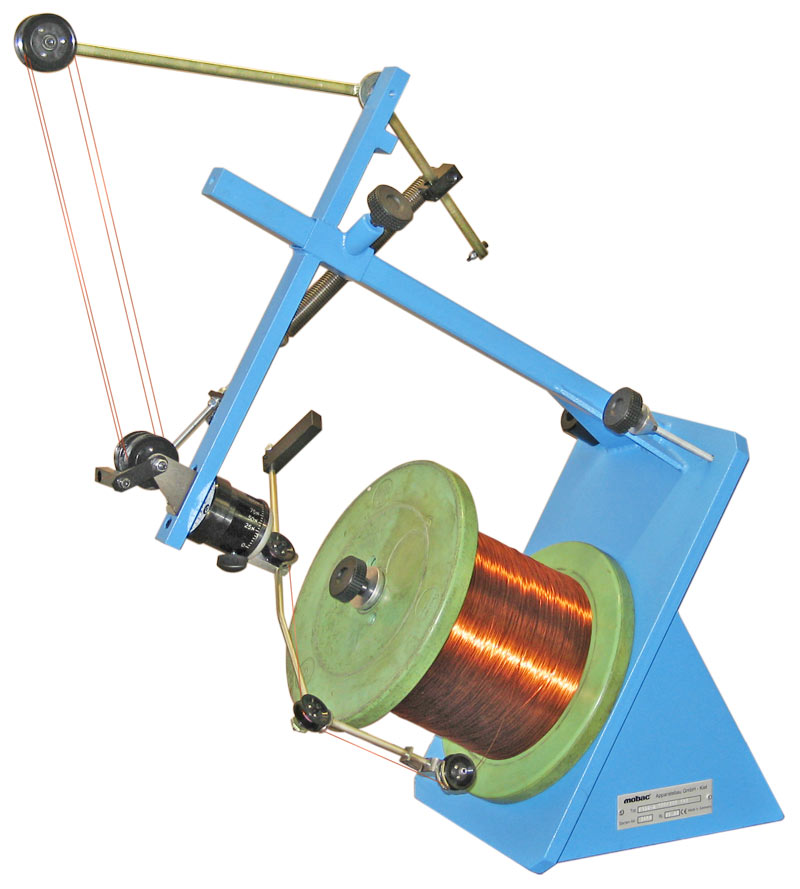

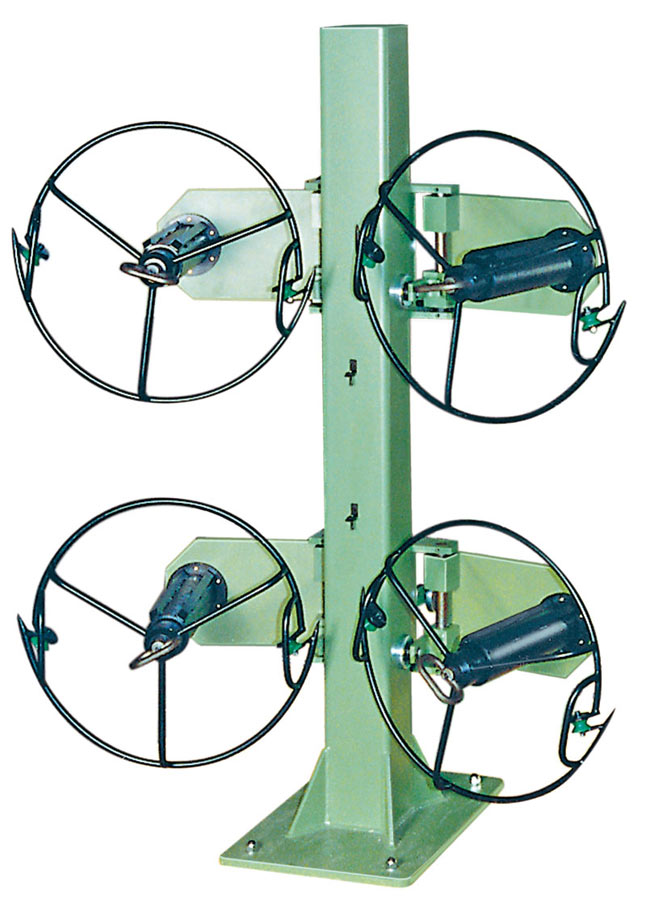

Flyers for Bobbin Hole

Flyers for Bobbin Hole are easy to use and allow quick changes. They are particularly suitable for flexible production processes and ensure efficient material handling.

Description

- Suitable for spool diameters up to 1250 mm

- Maximum wire speed: 800 m/min

- Wire tension range: up to 70 N

- Supported wire diameters:

- Copper and aluminum wire: 0.1 to 3.0 mm

- Steel wire (hard): up to 1.8 mm

- Steel wire (soft): up to 2.2 mm

- Multi-wire capacity: up to 24 x 0.65 mm

- Available brake types: Hysteresis brake, friction brake, magnetic particle brake with power supply unit

Optional

- Universally adjustable deflection roller

- Flyer for both directions of rotation

- for different spool bores

- Fast flyer arm made from fiberglass

- Compensator

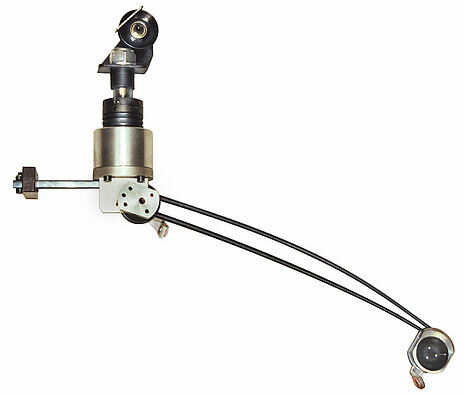

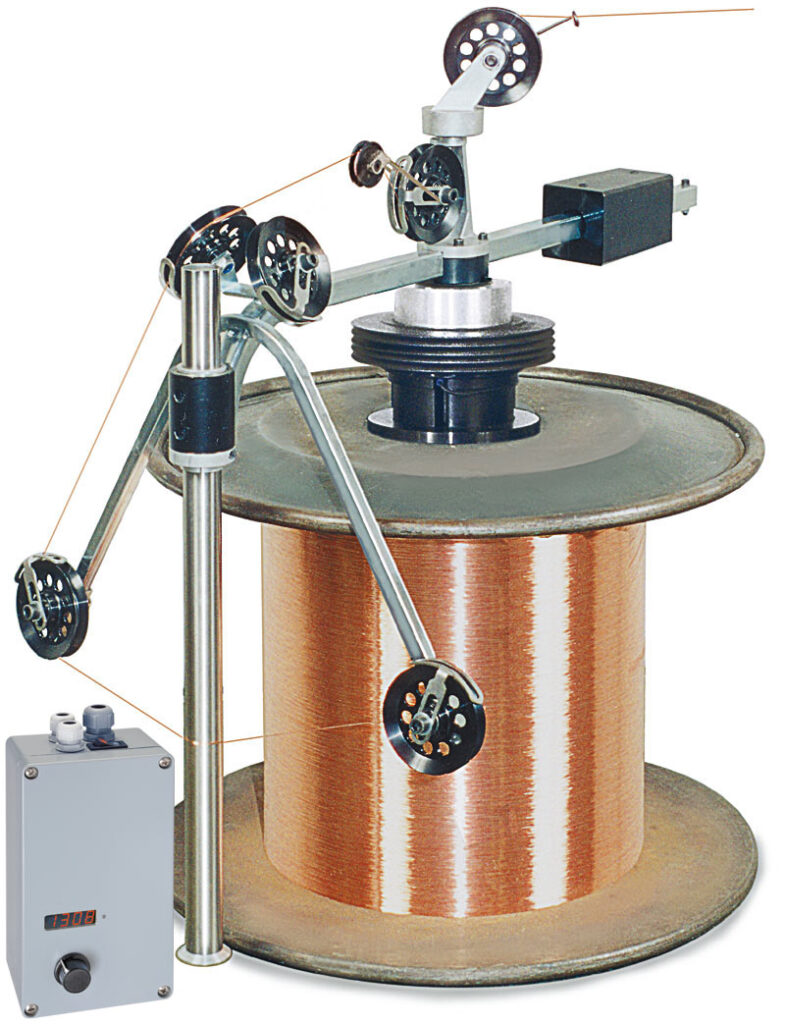

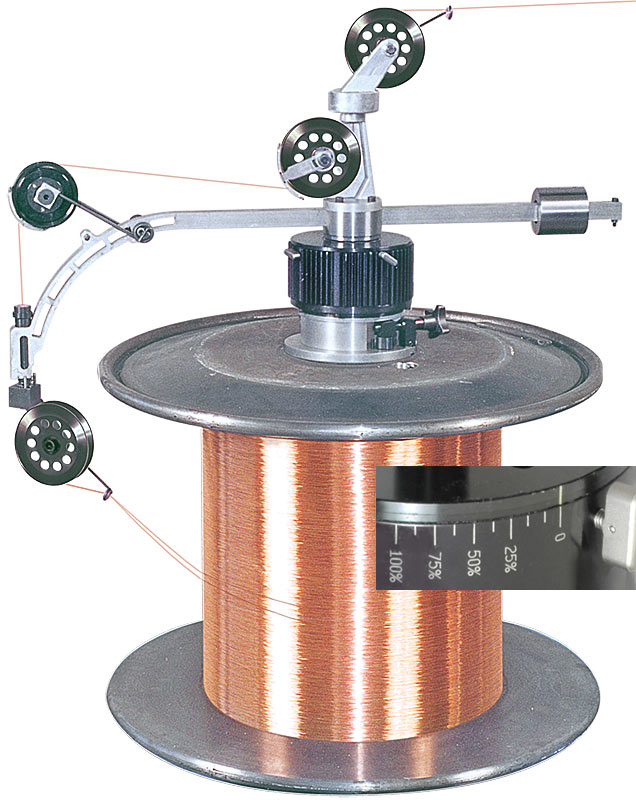

Flyer with tension control

Flyers with tension control ensure uniform tension of the material, even at high speeds. They are particularly suitable for sensitive materials such as wire or stranded wire.

Description

- Suitable for spool diameters from 400 to 1000 mm

- Maximum wire speed: 800 m/min

- Wire tension range: 1 to 50 N

- Supported wire diameters:

- Copper and aluminum wire: 0.1 to 1.8 mm

- Steel wire (hard): up to 1.0 mm

- Steel wire (soft): up to 1.5 mm

- Multi-wire capacity: up to 19 x 0.65 mm

- Equipment: echo control, dancer accumulator, driven fiberglass flyer arm

Optional

- Fast flyer arm made from fiberglass

- Tractive force display

- Drive (AC motor)

- Magnetic particle brake and power supply unit

- Wire break sensor

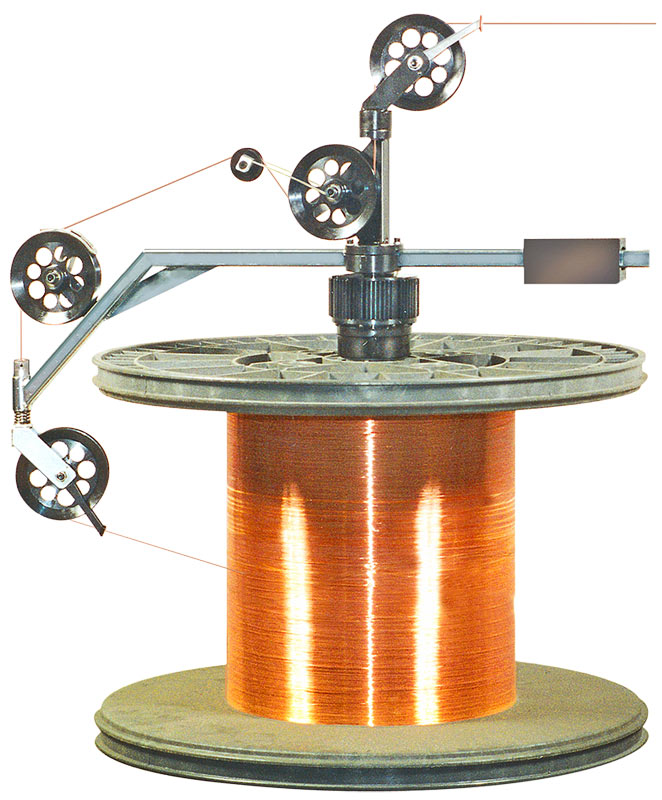

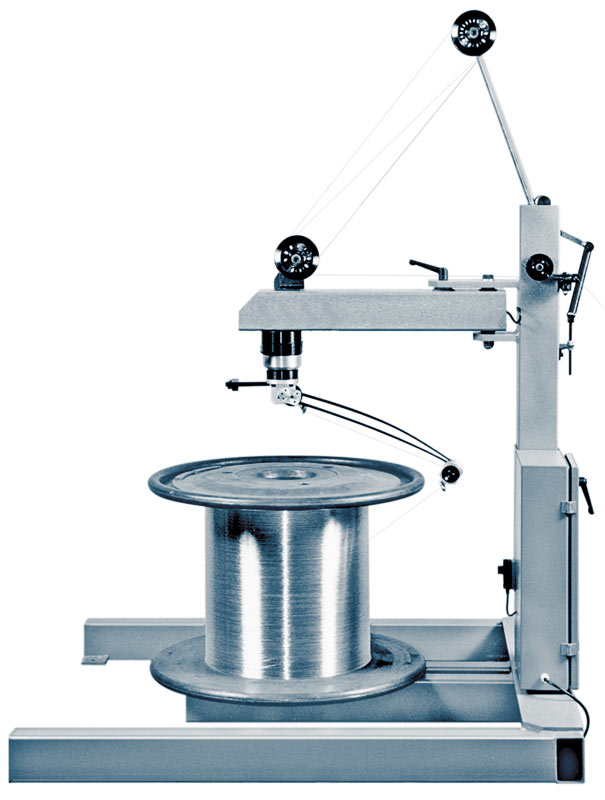

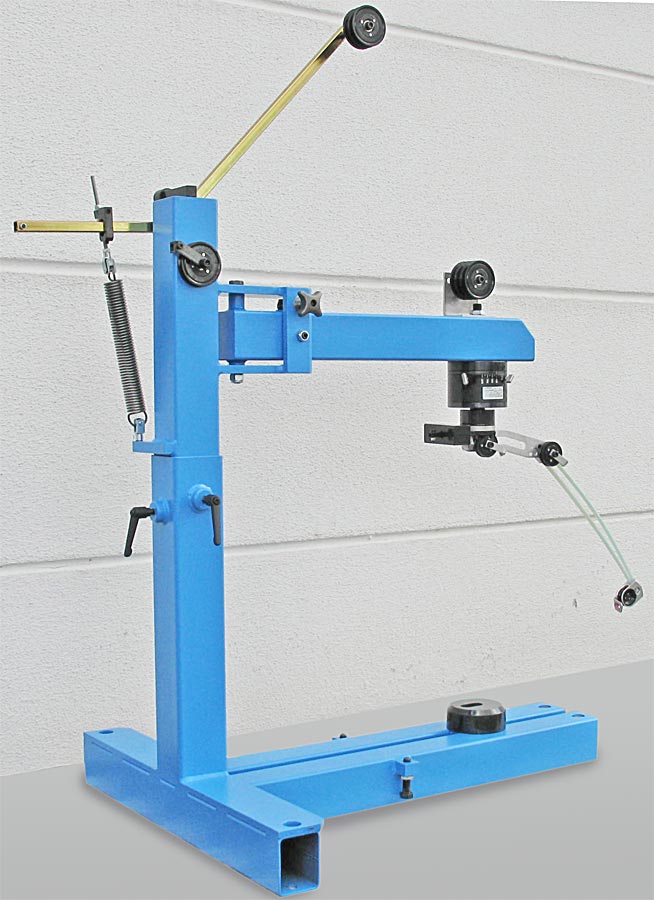

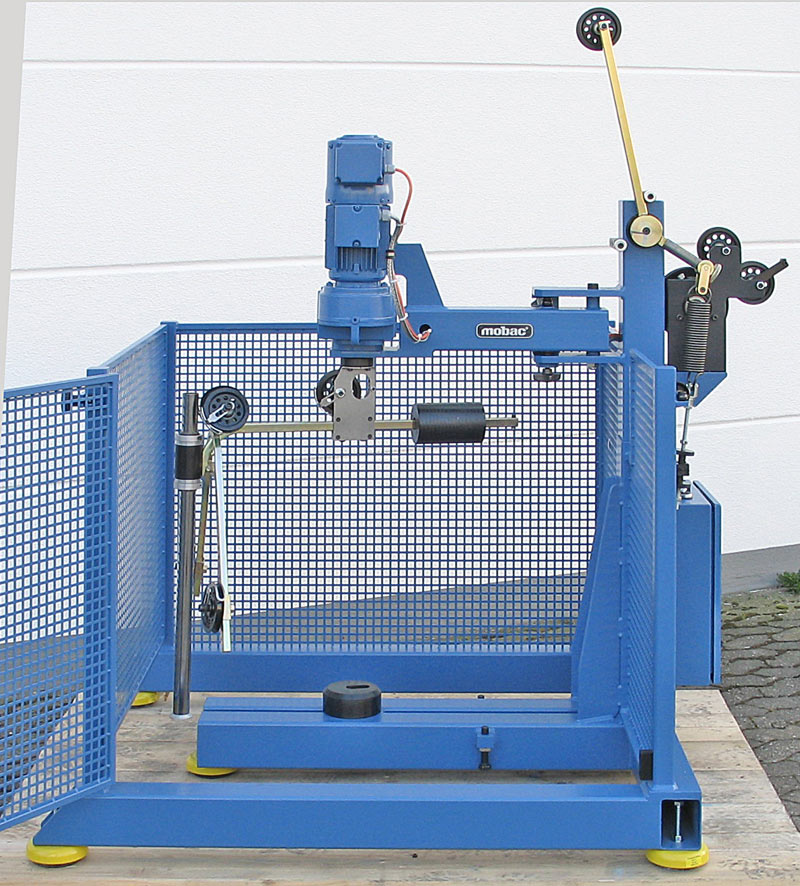

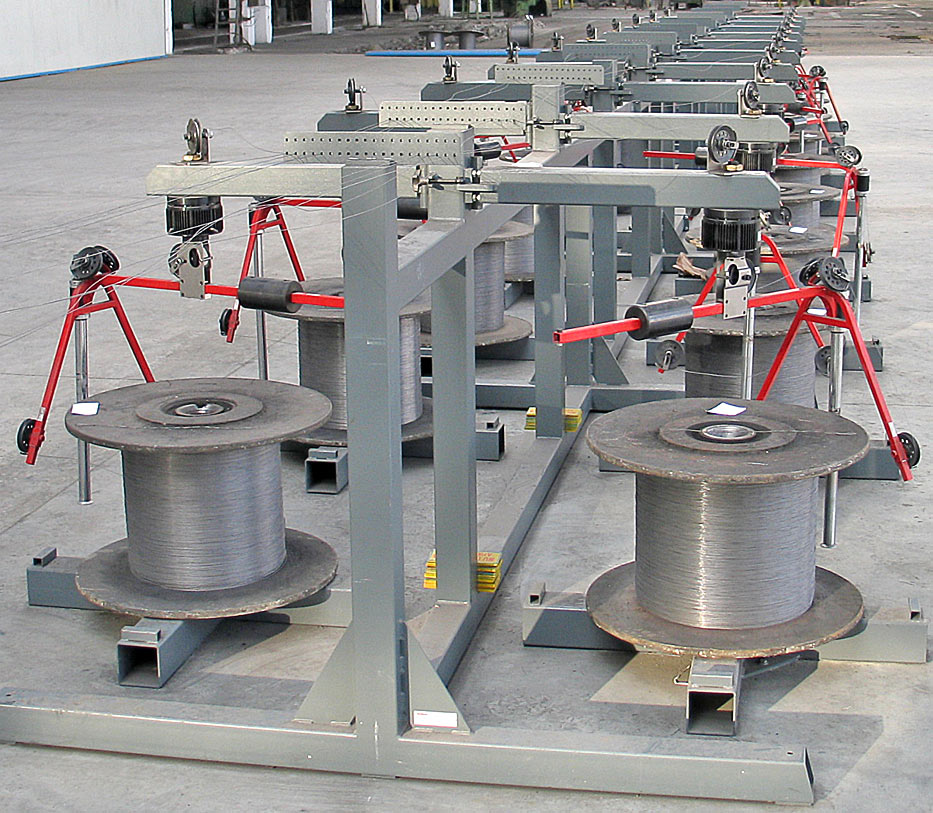

Single Payoff Frames

Individual Single Payoff Frames are space-saving and flexible solutions for payoff wire or cable. They offer stable material guidance for precise processing.

Description

- Suitable for spool diameters up to 1250 mm

- Maximum wire speed: 800 m/min

- Wire tension range: 1 to 70 N

- Supported wire diameters:

- Copper and aluminum wire: 0.1 to 3.0 mm

- Steel wire (hard): up to 1.8 mm

- Steel wire (soft): up to 2.2 mm

- Multi-wire capacity: up to 24 x 0.65 mm

- Available brake types: Hysteresis brake, magnetic particle brake

Optional

- Universally adjustable deflection roller

- Protective fence

- Fast flyer arm made from fiberglass

- Tension sensor and digital surface

- Wire break sensor

- stackable

- Dancer’s arm

- Compensator

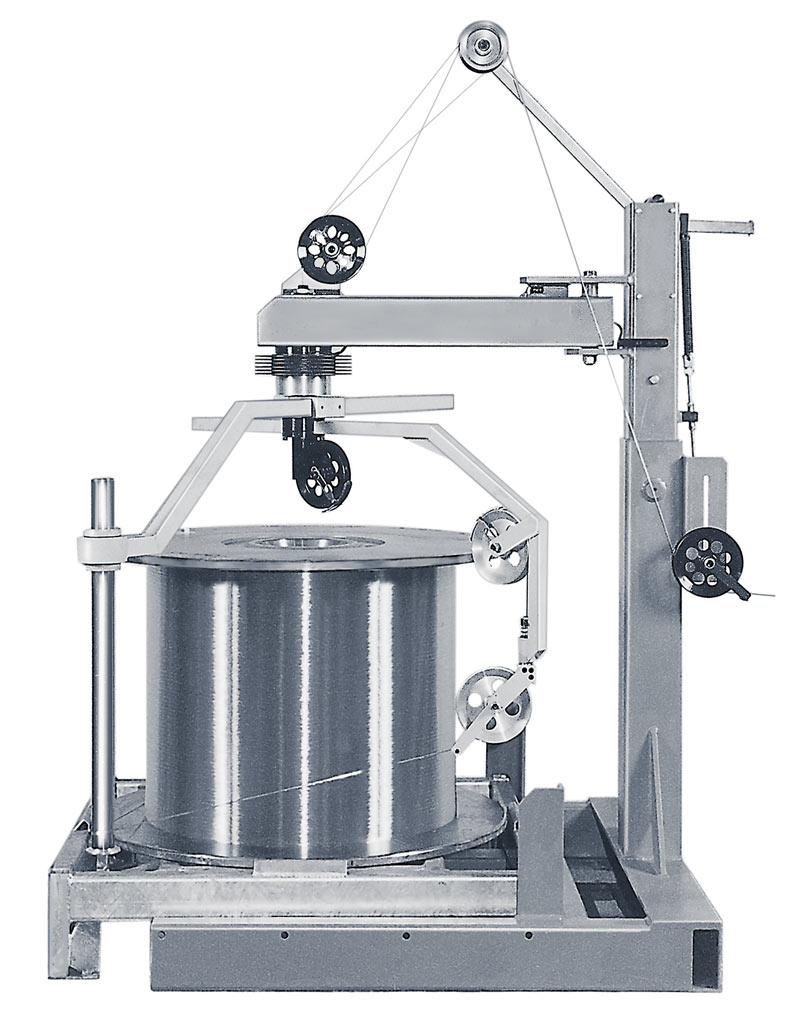

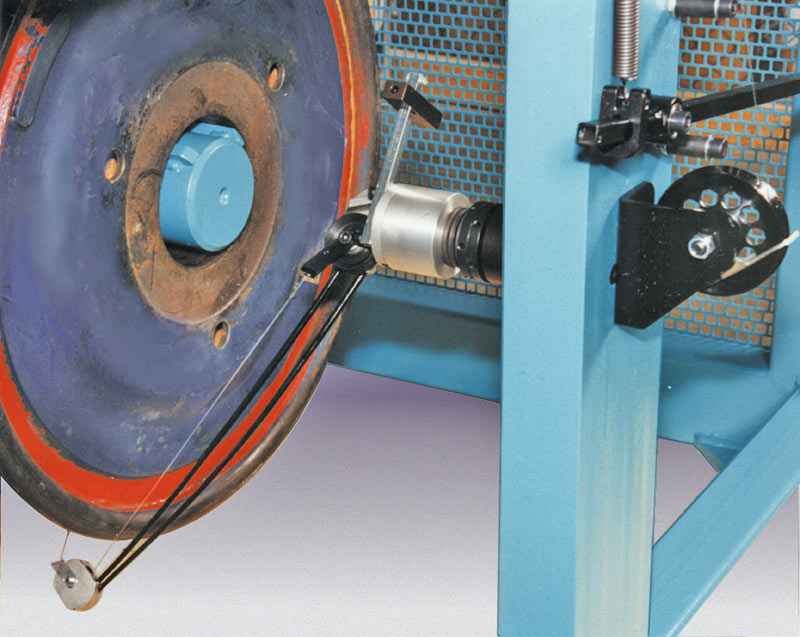

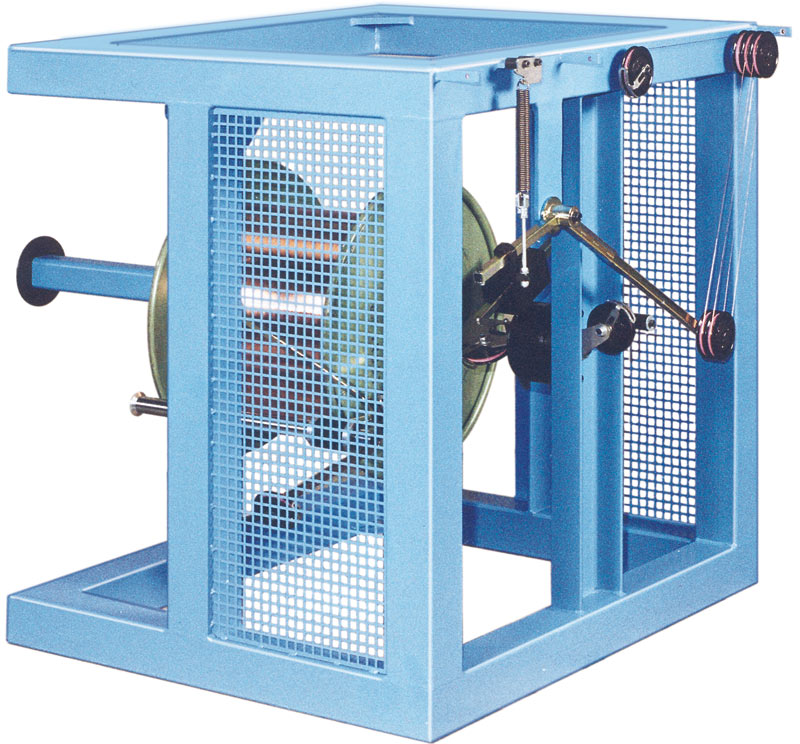

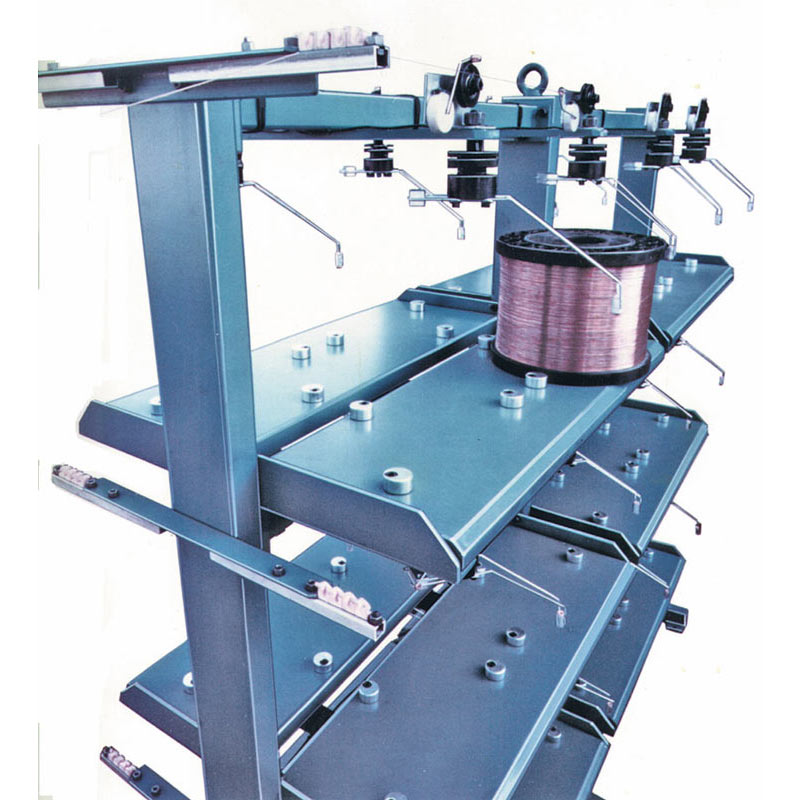

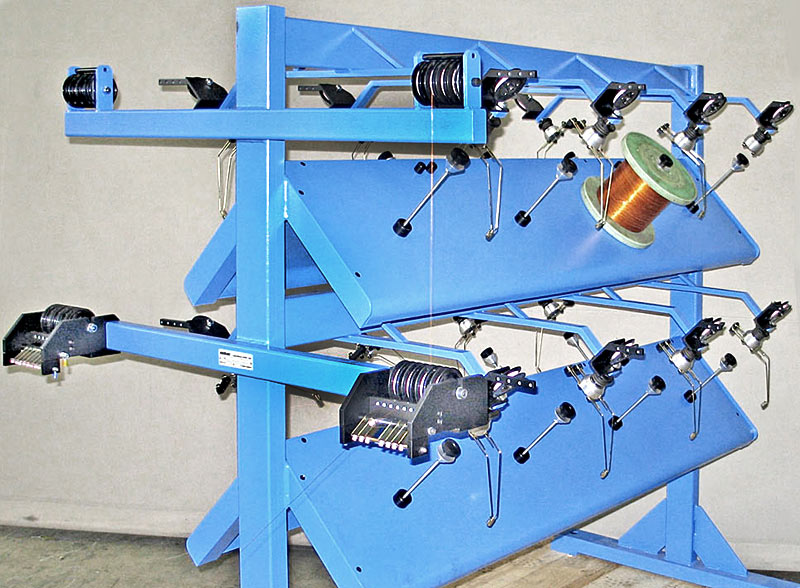

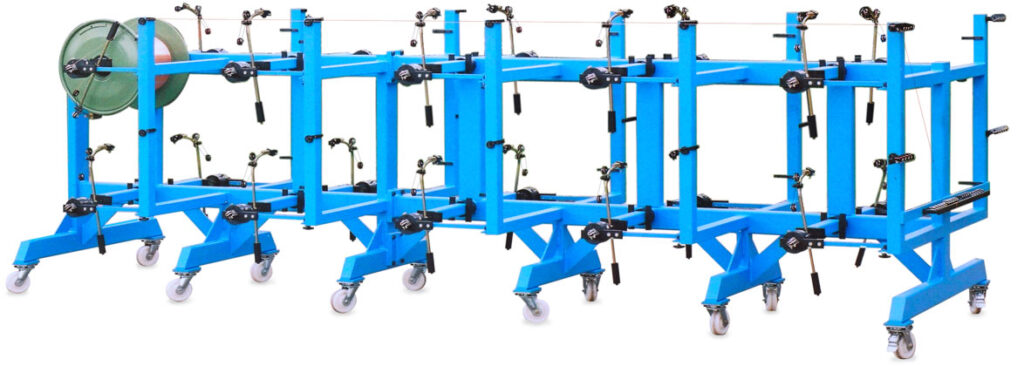

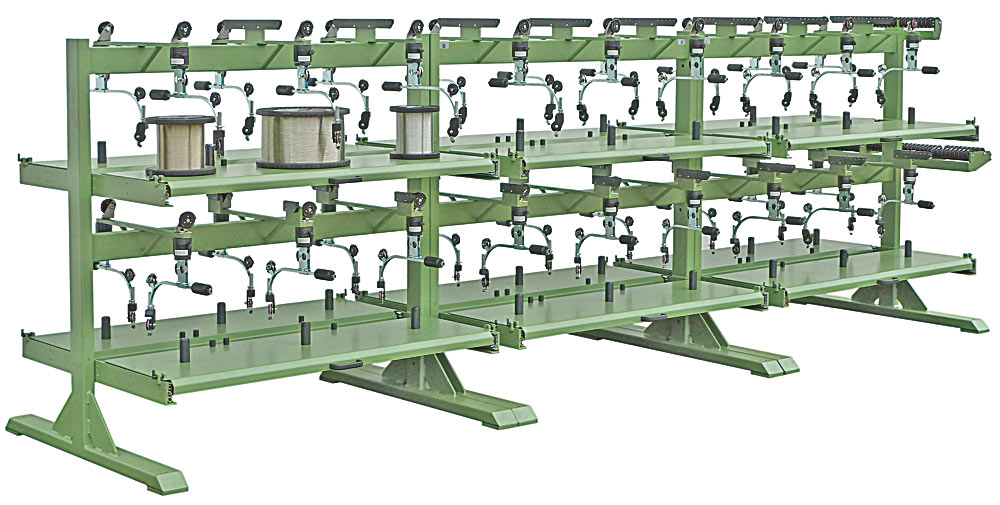

Multi Payoff Frames

Multi Payoff Frames allow several materials to be unwound at the same time. They are ideal for highly efficient production processes and increase productivity.

Description

- Capacity: 2 to 36 spool

- Spool diameter: 80 to 630 mm

- Maximum wire speed: up to 300 m/min

- Wire tension range: 0.4 to 50 N

- Spool arrangement: right and left

- Spool arrangement 1-3 levels

- Can also be executed as an endless sequence

- Unwinding flyer with hysteresis brake or magnetic powder brake and power supply unit

- Flyer arm adapted to spool size and wire diameter

Optional

- Number of spool positions as required

- Wire break sensor

- with swivel and brake castors under the frame

- customized design

High Speed Flyer Payoffs

Fast flyer processes ensure a high production speed with consistent precision. They are ideal for applications that require rapid material handling.

Description

- Suitable for spool diameters from 400 to 1000 mm

- Maximum wire speed: 800 m/min

- Wire tension range: 1 to 20 N

- Supported wire diameters:

- Copper and aluminum wire: 0.15 to 1.0 mm

- Steel wire (hard): up to 0.5 mm

- Steel wire (soft): up to 0.7 mm

- Multi-wire capacity: up to 8 x 0.65 mm

Optional

- Wire break sensor

- Compensator

- Dancer’s arm

- Fast flyer arm made from fiberglass

- powered flyer with AC motor

- Protective housing

- Hysteresis brake, magnetic particle brake and power supply unit

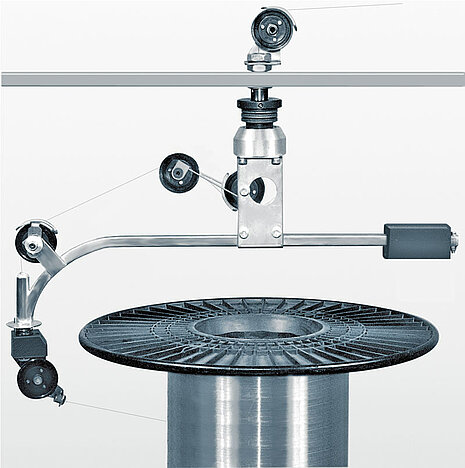

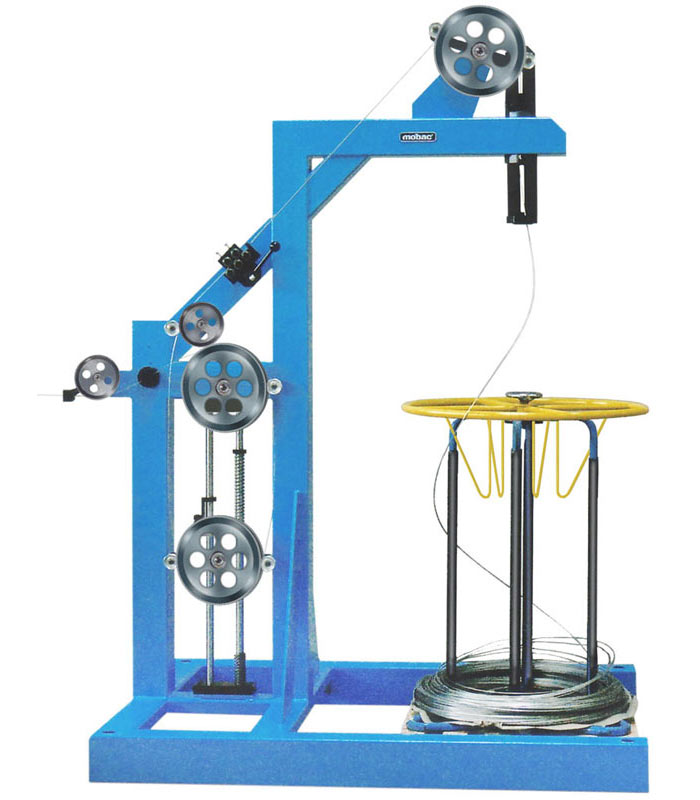

Coil Payoffs

Coil Payoffs offer a safe and even unwinding of wires and cables. They are characterized by their robust construction and versatility.

Description

- Suitable for coils on tail stocks

- Supported wire speed: up to 2.5 m/s

- Wire tension range: variable depending on application

- Supported wire materials: copper, aluminum, steel

- Supported wire diameters:

- Copper and aluminum wire: up to 5.3 mm

- Steel wire: up to 3.4 mm (soft)

- Dancer compensation system for even wire feed

- Tension adjustment by flyer arm braking or straightening rollers

- Robust design for industrial applications

- Precise unwinding mechanism for high process stability

- with ejector plate for the trail stock stand

Optional

- Customizable options depending on customer requirements

- Flyer arm

- Tail stock

Basket Payoffs

Basket Payoffs are specially developed for unloading material from baskets. They guarantee trouble-free material feed and are suitable for a wide range of applications.

Description

- Suitable for baskets with diameters from 530 to 1200 mm

- Maximum wire speed: up to 180 m/min

- Wire tension range: up to 50 N

- Supported wire diameters:

- Copper and aluminum wire: up to 4 mm

- Steel wire: up to 1.5 mm (soft)

- Height-adjustable support frames for flexible adjustment

- Robust design for industrial applications

- High process reliability and consistent processing

- Protective fence optionally available for additional safety

- Optimal solution for wire unwinding from baskets

Optional

- Optionally equipped with hysteresis brakes for higher tension

- Wire straightening rollers

- Swivel and brake castors

- Individually adjustable wire outlet height