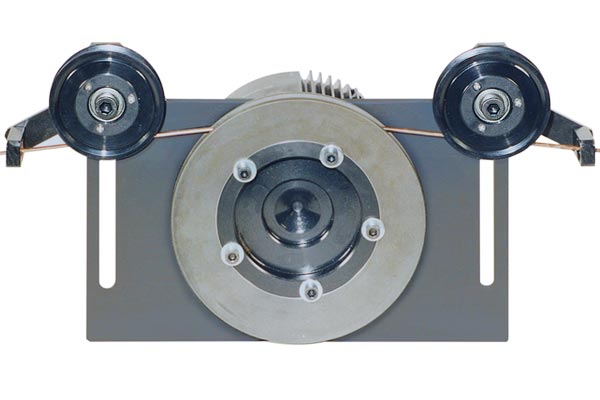

The mobac Winding Around Unit ensures uniform wire tension thanks to the combination of precise braking force control and robust winding around pulleys. It is ideal for applications that process delicate materials with high reliability and control and offers maximum flexibility with different wire diameters.

Details

The hysteresis brakes are designed for a temperature range of -30 to +85 °C.

- Used to equalize wire tension fluctuations and to build up tension before stranding

- Use of current controlled and permanent hysteresis brakes with adjustable torques

- Winding around pulleys with running surfaces made of hardened steel or ceramic, diameter from 60 to 300 mm

- Positioning rollers with ceramic or steel running surfaces, diameter from 20 to 166 mm

- Application for single wires and multi-strand wires

- Adjustable wire tension up to 500 N

- Maximum cable diameter up to 10 mm

- Compact and robust design for industrial use

- Easy integration into existing production lines

- Precise tension control for high-quality end products

- Maintenance-free operation thanks to high-quality materials

- Customizable to specific customer requirements

- High reliability and durability

- Temperature resistance for use in different environments

- Low moment of inertia for dynamic applications

- Compatible with various control and regulation devices

- Extensive documentation and support available

- 3D models available in STEP format for design integration

- Use in various industrial sectors such as mechanical engineering, automation and medical technology

- Special versions available for different applications

Optional

- Various sizes and torque ranges

- Customizable shaft and flange configurations

- Special versions for high temperatures or special ambient conditions

- with stand / holding frame

- Customized adaptations on request

Product examples

WA HB50-60-20, WA 523-100-40, WA 663-150-50, WA 663-140-80, WA5 655-98, WA-FAT1200-280/360