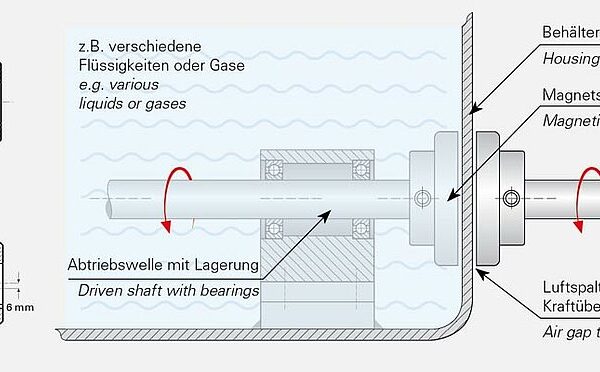

Magnetic Disk Clutch enable contactless and maintenance-free torque transmission. They compensate for misalignments and are ideal for closed systems such as pumps and agitators.

Details

- Non-contact torque transmission through non-magnetic walls

- Areas of application:

- Drive pumps, agitators or compressors in closed liquid containers

- Drive fans in closed containers with gases or vapors

- Power transmission to underwater robot arms

- Transfer of display processes to round scales in another medium

- Avoidance of motor vibration transmission

- Decoupling of weight influences during weighing processes

- Standard working temperature range: -40 to +140 °C (special version up to +280 °C)

- Compensation of alignment angle errors up to 3° and parallel offset up to 6 mm

- Made of stainless steel (material: 1.4005 / 1.4305 / 1.4401)

- Laser-welded SW types are resistant to salt water and made from 1.4401

- Available in sizes from MTD-0.2 to MTD-50

- MTD-0.2 to MTD-12 available from stock; MTD-20 to MTD-50 on request

- Supplied as individual clutch halves; specified weight includes magnets

- Transmission through walls only works with non-magnetic materials

- Magnetic disks can also be used as components of hysteresis brakes

- Simple, flat design enables versatile applications

- High efficiency in torque transmission

- Maintenance-free operation thanks to wear-free technology

- Simple integration into existing systems

- High reliability and durability

- Extensive documentation and support available

- 3D models available in STEP format for design integration

- Customizable to specific customer requirements

Optional

- Various sizes and torque ranges

- Laser-welded versions (SW types) for increased resistance

- Special versions for high temperatures or special ambient conditions

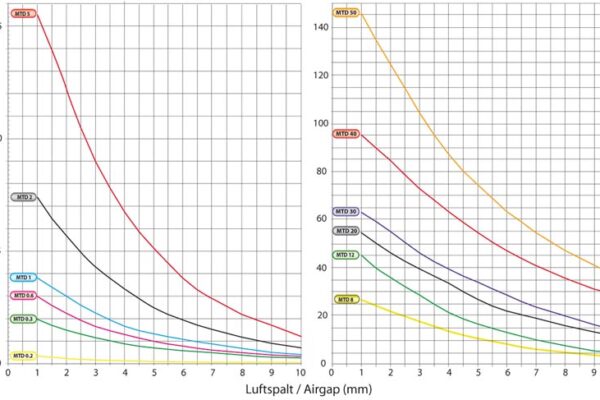

Torques / Axial forces

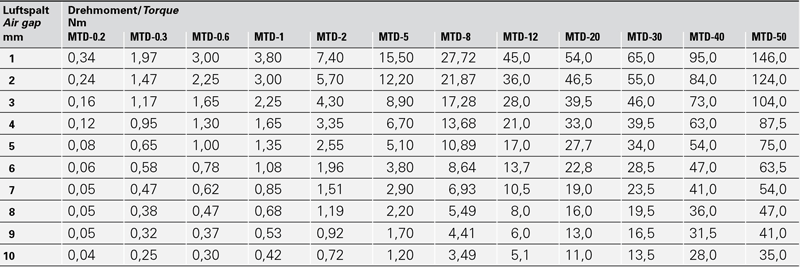

Torques:

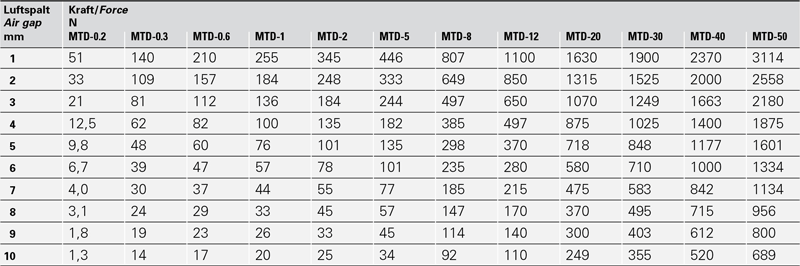

Axial forces: