Advantages and specific properties

The main advantage of these units is the contactless torque transmission, as the armature with the permanent magnetic hysteresis material is only immersed in the air gap of the magnet. Brakes are therefore mainly used in slip mode.

Mode of operation

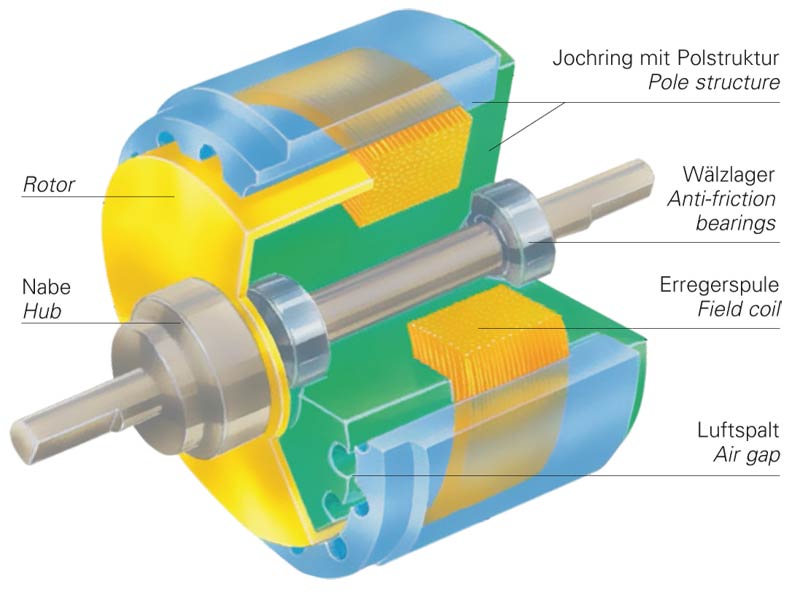

The mode of operation of externally excited hysteresis units is based on the magnetic force effect of attracting poles and constant remagnetization of a permanent magnetic “hysteresis material”.

Adjustable torque

The transmittable torque depends on the current in the exciter coil and is infinitely adjustable up to the respective maximum value. The torque is almost constant over the nominal speed range. A slight drop in torque when heated up is usually balanced out by a slight increase in torque at high slip speed.

Service life

Longer service life expectancy: Hysteresis brakes always generate torque via an air gap. This distinguishes them completely from friction lining brakes and magnetic powder units. There is therefore no wear and no sealing problems for the above-mentioned reason. Hysteresis brakes therefore have a much longer life expectancy.

Torque Repeatability

Best torque repeatability: As the torque is generated magnetically without touching materials, hysteresis brakes enable high torque repeatability. Friction lining brakes and magnetic particle brakes are normally subject to a greater or lesser degree of wear, with the result that repeat accuracy is lost.

Slip speed

Highest speed options: Hysteresis brakes enable the highest slip speeds of all electric torque transmission variants. Depending on the size, power loss and bearing load, speeds of well over 10,000 min can often be achieved. In addition, the full torque is available even without slip speed and is transmitted very smoothly at any speed.

Smooth running

As there is no mechanical friction or magnetic powder involved in hysteresis brakes, these units work particularly smoothly, no matter how high the proportionate slip speed is. This is seen as an advantage in most applications such as tension control in the packaging industry or for power transmissions in drive technology.