Structure and function

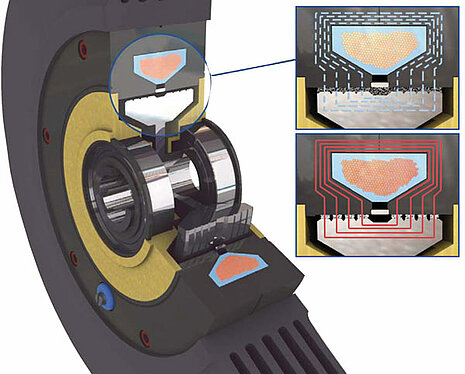

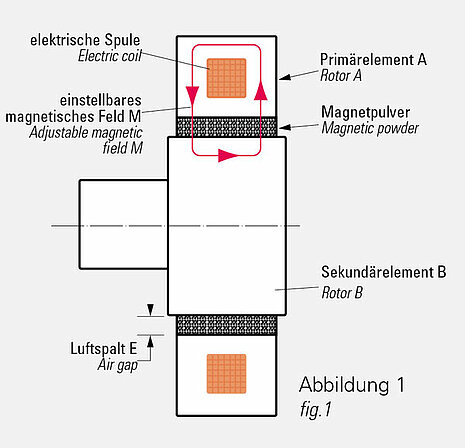

The magnetic particle brake and clutch is simple in design and achieves a high torque in a small space. The unit is made up of 2 independently mounted rotors. The outer rotor contains a ring coil which is supplied with direct current for actuation. There is a magnetized powder (ferro/chrome) in the air gap between the rotors. When the coil is energized, the magnetization causes the powder grains to form a kind of chain, whereby the stiffness of this chain varies with the magnetic field and is directly proportional to the level of the applied current. This creates a more or less strong braking adhesion between the two rotors, which achieve a transmission torque proportional to the current.

Advantages

- Silent operation

- Torque directly proportional to the excitation current

- Torque independent of speed (from 30 min)

- Robust construction, suitable for permanent slipping

- High torque control range of approx. 1:50

Applications

- Engaging and disengaging the clutch

- Brakes

- Torque control, torque limitation

- Tension control during winding and unwinding

- Targeted braking and starting

- of moments of inertia and masses