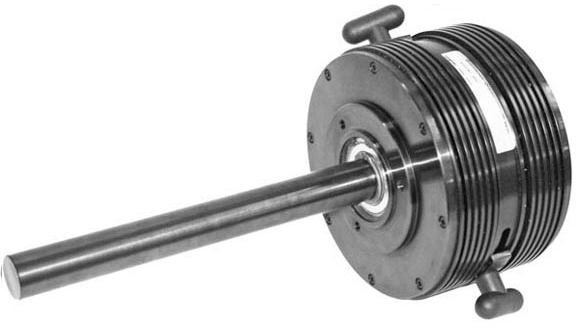

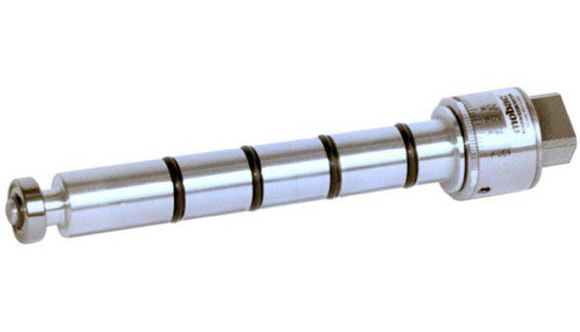

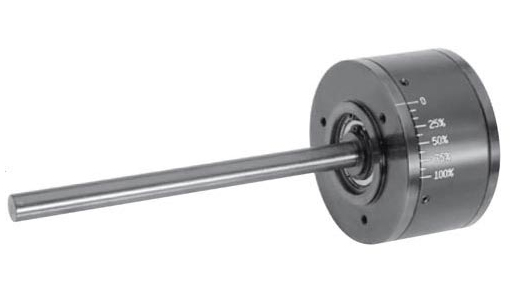

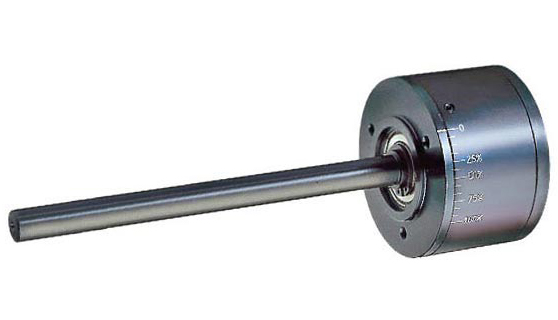

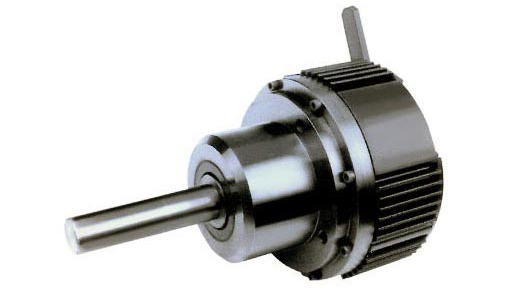

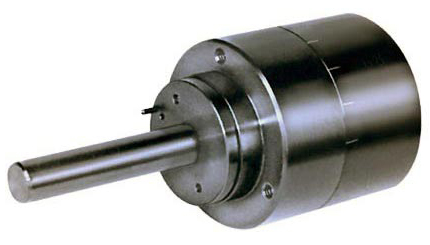

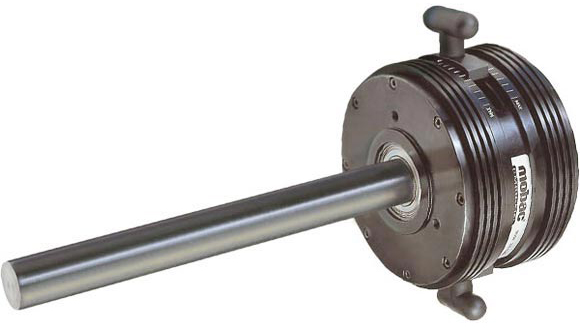

Permanent Hysteresis Brakes enable smooth and wear-free torque transmission. With presettable torques, they are ideal for precise applications in drive technology

Details

The hysteresis brakes are designed for a temperature range of -30 to +85 °C.

- orque range:up to 38 Nm

- Maximum power loss: up to 350 W

- Maximum speed: up to 4,000 rpm

- Presettable torques for precise applications

- Compact and robust design

- Maintenance-free operation thanks to wear-free hysteresis technology

- Constant torque output independent of the speed

- Simple integration into existing systems

- Various sizes and versions available

- Suitable for applications in winding technology, test benches and drive technology

- High control accuracy and reproducibility

- Temperature resistance for use in different environments

- Low moment of inertia for dynamic applications

- Optional customizations for specific customer requirements

- Available with different shaft and flange configurations

- Compatible with various control and regulation devices

- High reliability and durability

- Use in various industrial sectors such as mechanical engineering, automation and medical technology

- Extensive documentation and support available

- 3D models available in STEP format for design integration

Optional

- Various sizes and torque ranges

- Customizable shaft and flange configurations

- Special versions for high temperatures or special ambient conditions

- Customized adaptations on request

Technical data

| Type | Torque (Nm) | max. Permissible power loss (W) | max. Speed *(min-1) | Downloads | ||

| 513 | 0,001 – 0,014 | 2,2 | 4000 | STEP | ||

| 513-005 | 0,001 – 0,014 | 2,2 | 1000 | |||

| 520 P | 0,003 – 0,14 | 13 | 3000 | STEP | ||

| 520 PL | 0,001 – 0,08 | 13 | 3000 | STEP | ||

| 520 | 0,003 – 0,14 | 13 | 3000 | STEP | ||

| 520 L | 0,001 – 0,08 | 13 | 3000 | STEP | ||

| 527 | 0,007 – 0,14 | 13 | 3000 | STEP | ||

| 655 | 0,014 – 0,52 | 18 | 2000 | STEP | ||

| 523 | 0,06 – 1,36 | 28 | 1000 | STEP | ||

| 535 | 0,11 – 2,80 | 72 | 1000 | STEP | ||

| 610 | 0,14 – 4,50 | 95 | 1000 | STEP | ||

| 663 | 0,23 – 7,80 | 150 | 1000 | STEP | ||

| 953-002 | 0,05 – 0,38 | 18 | 500 | |||

| 651 | 0,03 – 0,14 | 13 | 1000 | STEP | ||

| The outer surface of the brake is coated with a wear-resistant polyurethane layer that has been developed and tested for these applications. | ||||||

| 600 | 0,23 – 1,36 | 28 | 1000 | STEP | ||

| The outer surface of the brake is coated with a wear-resistant polyurethane layer that has been developed and tested for these applications. | ||||||

| 608 | 0,68 – 7,80 | 140 | 1000 | STEP | ||

| 609 | 0,035 – 0,62 | 18 | 1000 | STEP | ||

| 880 | 0,15 – 1,46 | 28 | 1000 | STEP | ||

| 929 | 0,33 – 15,80 | 180 | 1000 | STEP | ||

| 300 | 3,0 – 38 | 350 | 1000 | STEP | ||

|

|

*depending on torque | |||||

We accept no liability for technical details.

Downloads

Catalog

Further product units

Installation and assembly

Product examples

Accessories

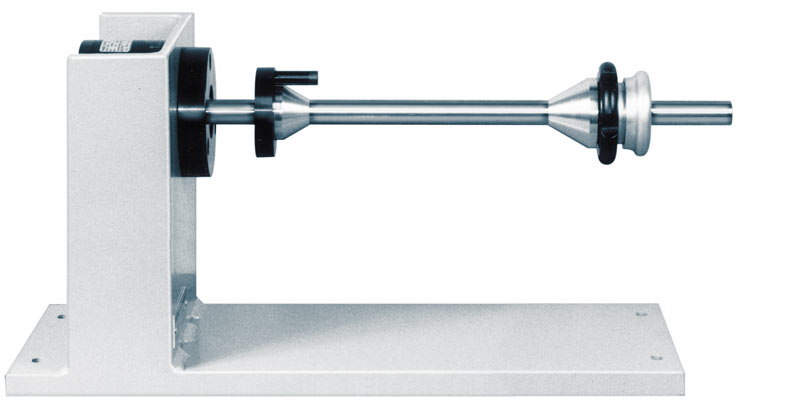

Mounting Frame for Hysteresis Brakes

mobac Mounting Frame for Hysteresis Brakes offer a stable and adaptable solution for the integration of hysteresis brakes in tangential sequences. They enable precise control of the wire tension and can be adjusted in height to accommodate different spool sizes. These frames are ideal for applications that require precise wire unwinding and tensioning.